Cellulose Products

SCYCLE's Advanced Cellulose Technology Solutions

MicroFibrillated Cellulose

Microfibrillated Cellulose

MFC is a nanomaterial obtained by mechanically microfibrillating cellulose fibers, featuring high aspect ratio, high specific surface area, and excellent mechanical properties.

Applications

Cellulose Nanofiber

Cellulose Nanofiber

CNF is cellulose fiber with nano-scale diameter, maintaining the crystalline structure of cellulose, with extremely high specific surface area and excellent mechanical properties.

Applications

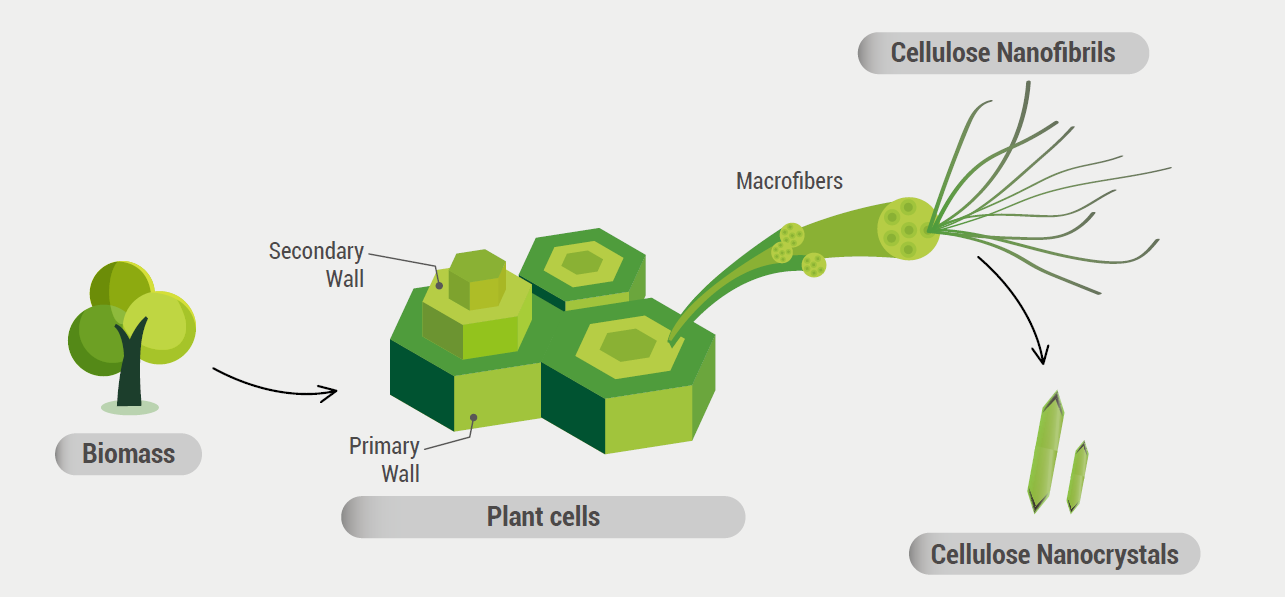

Cellulose Nanocrystal

Nanocellulose Crystal

CNC is highly crystalline nanocellulose obtained through acid hydrolysis, featuring rigid rod-like structure and unique optical properties.

Applications

Technical Specifications

CNF vs CNC Technical Comparison

CNF - Cellulose Nanofiber

Features fiber form, aspect ratio 1/100 or larger

Manufacturing Process: Uses mechanical methods, fiber structure maintains original state

CNC - Cellulose Nanocrystal

Features crystal form, aspect ratio 1/50 or smaller

Manufacturing Process: Produced through acid hydrolysis reaction (treated with sulfuric acid, etc.)

Manufacturing Difference Explanation

The morphological differences between CNF and CNC are caused by their manufacturing methods. Since CNF uses mechanical methods, the fiber structure can maintain its original state; while CNC is produced through acid hydrolysis reaction, where amorphous regions are dissolved by strong acid, leaving only crystalline regions. Although different scholars have varying standards for distinguishing CNF and CNC, they are generally differentiated by shape and aspect ratio (Diameter/Length).

CNF vs CNC Morphological Structure Comparison Diagram

Bacterial Nanocellulose

Bacterial Nanocellulose

BNC is pure nanocellulose produced by bacterial fermentation, featuring unique 3D network structure and excellent biocompatibility.

Applications